Inicio » Sight Windows

Sight Windows

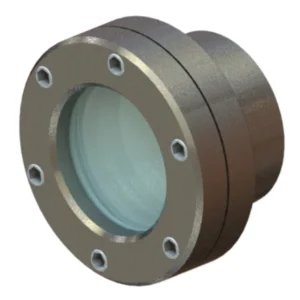

The Iniflu tank sight window is a high-quality level viewer designed for easy installation on tanks with flanged connections. This innovative product provides a clear visual inspection of the tank’s interior, offering essential control of fluid levels and processes without requiring complex installation procedures.

We offer a cost-effective solution for monitoring fluids in hydraulic systems, gearboxes, compressors, and other machinery, ensuring optimal performance and extending the lifespan of essential equipment.

We offer flanged, solderable, and sanitary connections, as well as specialized options such as SMS, DN, and LED vision windows.

They provide visual access to the internal processes of tanks and vessels, allowing operators to monitor fluid levels, detect anomalies, and ensure optimal performance.

The steel parts of our vision windows are made from stainless steel 304, 316L, or carbon steel with a corrosion-resistant coating. The glass can be quartz, tempered borosilicate (according to DIN 7080), tempered soda-lime glass, or polycarbonate.

Yes, depending on the type of connection and material, our vision windows can be designed for high-pressure applications. Contact us for specific pressure ratings.

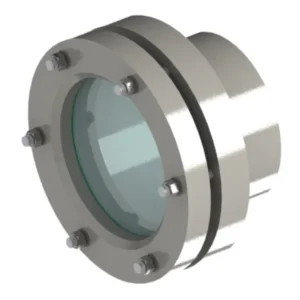

- The ZW15 model is designed for applications up to 150 PSI and uses hidden Allen screws for a cleaner look and a larger viewing area.

- The ZW30 model, rated for 300 PSI, uses pressure washers and nuts, with a larger glass seat and higher pressure resistance.

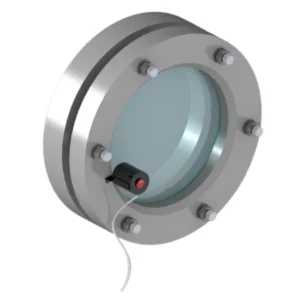

Iniflu offers vision windows with LED Vision, providing enhanced visibility in low-light environments, ideal for monitoring critical processes in real-time.

Yes, we can manufacture custom vision windows according to the exact specifications of your application. We maintain a range of standard sizes for quick response times, but we also offer custom solutions for special applications.

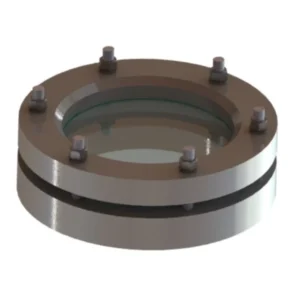

Iniflu's flanged vision windows consist of three parts: the flange on the tank, the bottom flange, and the cover flange. The bottom flange, which is not welded, is designed with the same dimensions as a standard flange but adapted to accommodate the bolts and the glass. Installation is straightforward, as the bottom flange is screwed directly onto the tank flange, forming a "sandwich" structure.

It is very easy to obtain spare parts for our standard products, as we keep most of them in stock. For custom-made parts, replacements typically take 1 to 2 weeks to prepare.

NEED TO REPLACE JUST THE SIGHT GLASSES?

NO PROBLEM

We offer replacement parts for both Iniflu equipment and other brands.