Flow indicators are devices used in piping systems to provide a visual indication of the flow of liquids, gases, or slurries within the system. They are crucial for monitoring and verifying the flow and condition of the medium without interrupting the process.

The double window flow indicator allows for greater flexibility in terms of gasket types and sight glass options, enabling higher usage parameters in terms of pressure ratings and high-temperature applications.

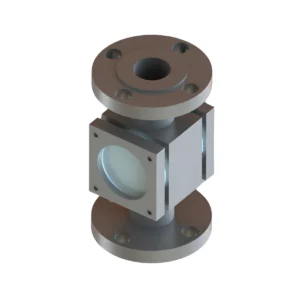

Visual Flow Indicators – Model HP

The Iniflu HP double window flow indicator features a one-piece forged body, providing enhanced robustness and durability. Additionally, the flanges are welded to the ends of the forged pipes, allowing this model to accommodate a flange type for every specific application.

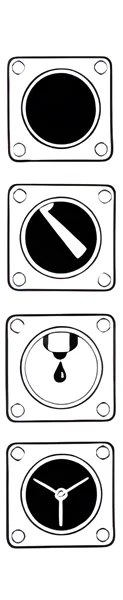

Add-ons to Enhance Flow Visibility

These visual flow indicators can include additional features that help users achieve a clearer view of the process.

Full View

Designed for easily visible fluids with color, turbulence, and clarity. These indicators easily detect the presence of solids or foreign particles in the fluid being handled. They can be installed in any position.

Flapper

Internally mounted with a PTFE paddle, its position indicates the fluid’s direction. Ideal for clear fluids that are difficult to observe. Typically installed horizontally and only mounted vertically for upward fluid flows.

Drip

These indicators allow the formation of droplets for low-volume or intermittent fluids, such as in unit distillation operations. They are mounted exclusively in a vertical position for downward flows.

Spinner

Internally mounted with a PTFE turbine that rotates as the fluid passes through, greatly facilitating the observation of dark, translucent, and clear fluids that are difficult to see with the naked eye. They can be installed in any position, either horizontally or vertically.

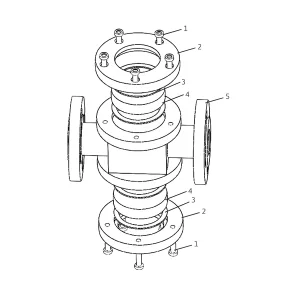

| Item | Part name | Material options |

|---|---|---|

| 1 | Bolts | Stainless Steel 316L HSS |

| 2 | Covers | Stainless Steel 304 Carbon Steel w/ coating |

| 3 | Gaskets | Graphite Neoprene Teflon Sanitary Rubber EPDM Viton |

| 4 | Sight Glass | Tempered Borosilicate Tempered Soda Lime Quartz |

| 5 | Body | Staineless Steel 316L Stainless Steel 304 Carbon Steel w/ coating |

Dual Window Sight Flow Indicators

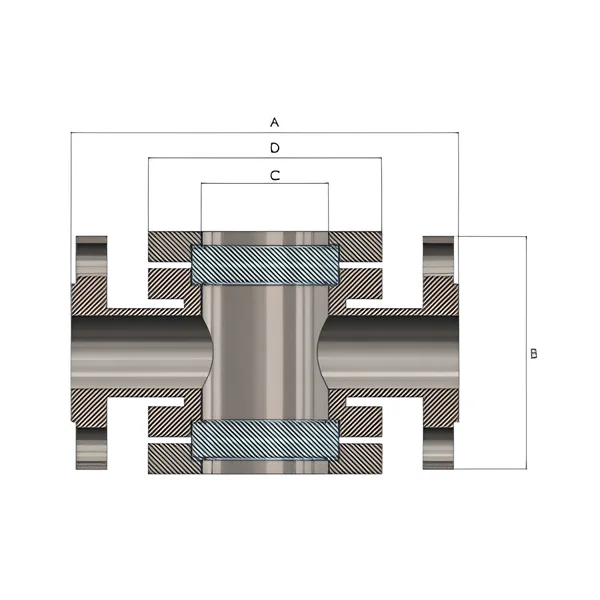

| Double Window Sight Flow Indicator – Technical Information | |||||

|---|---|---|---|---|---|

| Medidas | 1″ | 1 – 1/2″ | 2″ | 3″ | |

| A (Distance between faces) | 7″ (177.8 mm) | 8″ (203.2 mm) | 9″ (228.6 mm) | 9″ (228.6 mm) | |

| B (Distance between covers) | 5″ (127.0 mm) | 5.5″ (139.7 mm) | 5.5″ (139.7 mm) | 5.5″ (139.7 mm) | |

| C (Visible process) | 2″ (50.8 mm) | 2.5″ (63.5 mm) | 3″ (76.2 mm) | 3″ (76.2 mm) | |

| D (Diameter of covers) | 4″ (101.6 mm) | 4.5″ (114.3 mm) | 5″ (127.0 mm) | 5″ (127.0 mm) | |

| Glass (Total Diameter) | 2.5″ (63.5 mm) | 3″ (76.2 mm) | 3.5″ (88.9 mm) | 3.5″ (88.9 mm) | |

| Glass (Glass thickness) | 5/8″ (15.87 mm) | 5/8″ (15.87 mm) | 5/8″ (15.87 mm) | 5/8″ (15.87 mm) | |

Depending on the type of fluid, they can have a free passage type view, where the flow is appreciable and anomalies are sought to be inspected; rotor type, where the fluid is translucent and inspection is sought to ensure that there is flow; fin type, an alternative to the rotor that measures the intensity of the flow; and drip type, for gases.

The indicators are forged in one piece, which guarantees excellent resistance to pressure and more adverse conditions.

They are manufactured for flanges of 1″, 1-1/2″, 2″ and 3″. Depending on the operating conditions, types of gaskets and glass will be recommended.

Discover a wide range of solutions designed to optimize flow monitoring in your industrial applications. Our products stand out for their durability, versatility, and precision, making them the ideal choice for demanding environments.