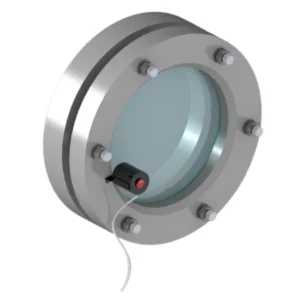

Sight glass wipers are designed for tanks where steam or gases emitted from the system may cloud the visibility through the flat sight glass. These sight glasses are equipped with a mechanism that allows the glass to be cleaned without needing to disassemble the equipment or stop the flow.

The wipers remove residues or particles adhered to the glass, maintaining optimal and safe visibility during monitoring. This feature is particularly useful in industries where material buildup, such as in petrochemical, food, or pharmaceutical industries, can obstruct visibility and compromise process safety.

Do Sight Glass Wipers Support High-Pressure Work?

It’s important to note that sight glass wipers are not designed for high-pressure operations. The tempered borosilicate glass loses its properties when bored in the center. The wipers are made of stainless steel and feature a Teflon-coated extendable cleaning mechanism for effective cleaning.

Sight Glasses with Wiper for Tanks

| Body Materials | PTFE / FKM |

| Wiper Materials | Allen Screws |

| Glass Materials | Borosilicate, Fluorosilicate, Quartz, Tempered Glass, Polycarbonate |

| Connection Type | Tank Sight Glass |

| Internal View Type | Free Pass |

| Working Pressure | From 0 to 300 PSI |

| Working Temperature | -45°C – 250°C |

Aquí tienes el texto traducido al inglés:

These sight glasses with wiper not only facilitate visual inspection in critical environments but also optimize maintenance times and enhance operational safety. By minimizing the need for manual cleaning of the sight glasses and reducing system downtime, companies can save significant time and operational costs. With proper installation, these devices offer durability, resistance to extreme conditions, and contribute to more precise and effective quality control.

At Iniflu, we value open and effective communication. If you have any questions or need additional information about our products and services, please feel free to contact us. We are here to assist you and address your needs.